28 Jun Ways Technology is Reducing Waste of Pharmaceutical Products

Already a $44 billion market, the pharmaceutical cold chain is still growing rapidly. In fact, cold chain storage companies are set to outpace the rate of growth of the traditional supply chain industry. Considering how important cold chain storage technologies are to today’s economy, it’s crucial to understand exactly what cold chain storage is, how companies use it to transport goods, and what technologies make it safe and reliable.

Given global supply chain concerns, it’s no surprise that cold chain storage warehouses and facilities are also encountering their fair share of challenges. Warehouses and storage facility maintenance are crucial to upholding the quality and integrity of pharmaceutical products that are vulnerable to temperature or environmental fluctuations.

The ways in which companies range the waste of pharmaceutical products ranging from obvious to innovative. To understand the significance of the many technologies used, it’s necessary to explore what cold chain storage is and why it’s so important.

Table of Contents

The Importance of Cold Chain Storage

The term cold chain storage refers to the logistics and procedures associated with creating a temperature-controlled supply chain. Products that pass through cold chain storage must be kept within predetermined temperature ranges to prevent their expiration or chemical breakdown. Cold chain storage is particularly important in the pharmaceutical industry since many medications must be stored at low temperatures throughout their supply chain journey.

The term cold chain storage refers to the logistics and procedures associated with creating a temperature-controlled supply chain. Products that pass through cold chain storage must be kept within predetermined temperature ranges to prevent their expiration or chemical breakdown. Cold chain storage is particularly important in the pharmaceutical industry since many medications must be stored at low temperatures throughout their supply chain journey.

The cold chain has been thrust into the spotlight during the COVID-19 pandemic due to the fact that COVID-19 vaccines must be stored at low or ultra-low temperatures. The Pfizer COVID-19 vaccine, for example, should ideally be stored at approximately minus 70 degrees Celsius.

Many investors have seen this need for cold chain technology and have begun making significant investments in the companies that produce them. However, it’s not only freezer technology that goes into making reliable cold chain storage possible. What are some of the other tools and procedures that cold chain managers use?

Sanitation and Automation

Sanitation is extremely important when it comes to pharmaceutical cold storage. In fact, sanitation is not just necessary for quality assurance, but also for regulatory purposes. Pharmaceutical companies must uphold certain sanitation standards to abide by Current Good Manufacturing Practices (CGMP) put forth by the Food and Drug Administration (FDA). This is true even for manufacturers that are struggling financially.

Proper sanitation practices protect the quality and potency of drugs. Poor sanitation can result in microbial growth and pharmaceutical product contamination that put patients in danger. If a pharmaceutical company is found to have poor sanitation during a warehouse inspection, that storage facility will have to be shut down until the issue is resolved.

Continued violations can cause a pharmaceutical warehouse to be closed permanently, causing huge financial losses and decreases in productivity. Many technologies are now being implemented to boost efficiency by automating repetitive tasks that are part of the cold chain process.

Management and Product Safety

Pharmaceutical warehouses and cold chain storage facilities must be managed smartly by competent leadership teams. Poor management can cause productivity slowdowns, regulatory infringements, and even product loss due to material spillages. Good management must also set up effective training protocols that teach personnel how to handle pharmaceutical products carefully.

Pharmaceutical warehouses and cold chain storage facilities must be managed smartly by competent leadership teams. Poor management can cause productivity slowdowns, regulatory infringements, and even product loss due to material spillages. Good management must also set up effective training protocols that teach personnel how to handle pharmaceutical products carefully.

For example, some pharmaceutical products must be handled with specialized equipment since the body heat from the touch of a worker’s bare hands could cause their temperature to increase beyond safe ranges.

Careful training ensures product safety. Pharmaceutical warehouses should have separate dedicated areas of operation for handling and storing products. According to Dickson, only authorized workers trained in cold storage for pharmaceuticals should be allowed access to sensitive medical products.

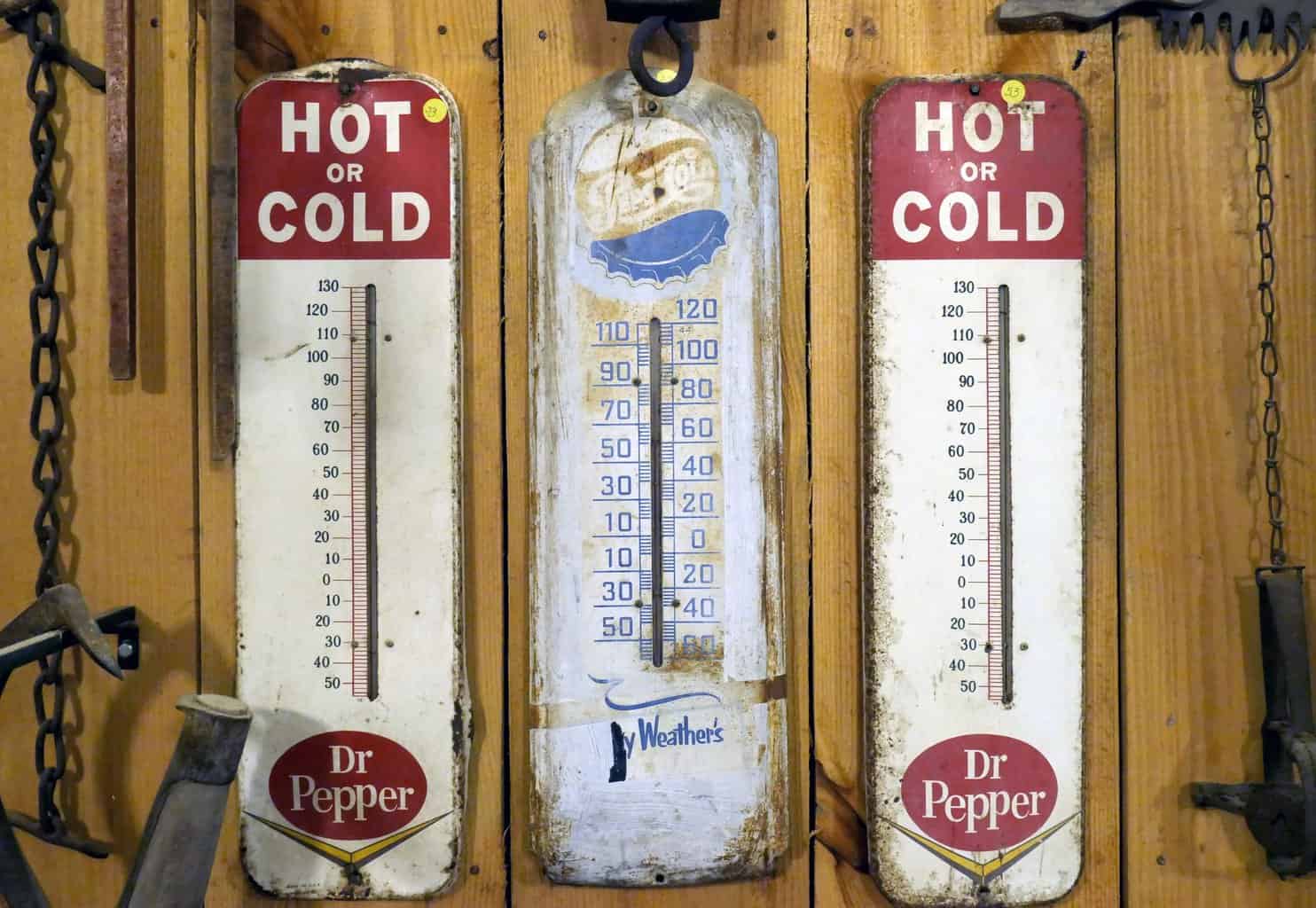

Temperature Control and Data Loggers

When storing temperature-sensitive pharmaceutical products, companies must keep warehouses within certain predetermined temperature ranges. To do so, it’s often best to use data loggers. Data loggers are small, electronic devices that collect and record environmental data – such as temperature, humidity, and differential pressure – from their surroundings.

Data loggers should be set up and maintained in storage areas that house temperature-sensitive products. The data loggers must be monitored, and the data they collect should regularly be transferred to external computer systems so that they can be analyzed, formatted, and submitted to regulators.

In fact, regulators require pharmaceutical companies to submit this data if they’re shipping products subject to environmental changes. It’s best to take steps to encrypt or secure sensitive data, especially when using internet-connected data loggers, to prevent expensive data recovery efforts or privacy concerns down the road.

In fact, regulators require pharmaceutical companies to submit this data if they’re shipping products subject to environmental changes. It’s best to take steps to encrypt or secure sensitive data, especially when using internet-connected data loggers, to prevent expensive data recovery efforts or privacy concerns down the road.

These data loggers can be used not only for cold storage, but also for cold transport, cold processing, and cold distribution. Regulatory bodies like the Department of Transportation, the International Air Transport Association, and the Transportation Security Administration all have requirements for how products get stored. These regulations primarily pertain to five areas: product stability, packaging, transportation, monitoring, and temperature minimums.

Pallet tracking based on RFID systems, gel packs, eutectic plates, dry ice, liquid nitrogen, and quilts are other technologies that can be used to monitor products and keep them at desired temperatures. In many cases, companies can buy data loggers and cooling technologies from authorized manufacturers, as well as tools that are approved by regulators. Sometimes, it might be necessary for pharmaceutical companies to design, patent, or develop their own customized solutions that safeguard the quality of their medical products.

Many sophisticated technologies are being used today to facilitate pharmaceutical cold chain storage. These tools help reduce waste by ensuring products are stable and well preserved while getting delivered to patients. Without these technologies, many companies would be forced to dispose of expired or degraded products, a significant sunk cost for the industry.

No Comments